Composite screw

Due to the ever-increasing number of new types of adhesive and abrasive materials and where it is not possible to use an axisless spiral due to the necessary filling with the transported material, we use robust plastic screw conveyors RATAJ® (Types RP, RPN) consisting of plastic segments forming the screw box and pipeline. These segments slide onto the hexagonal shaft in a very simple way and with the help of locks create a very robust structure of the screw conveyor without bearings.

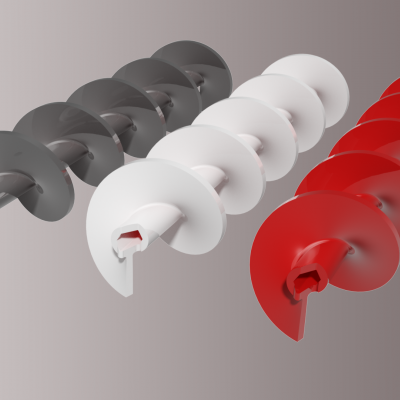

These conveyors are also used for demanding applications for transporting abrasive materials. Their main advantage is mainly light construction and quiet operation. The plastic auger is several times lighter compared to the steel spiral, and in combination with the corresponding pipeline, these conveyors can also be used for applications that require continuous operation of the conveyor without transported material. The main use is primarily in the food industry (sticky and moist materials), in the chemical industry (aggressive substances) and, last but not least, in heavy industry, energy and construction. For food, the segments are white and have a food certificate for contact with food, red segments are intended for abrasive materials, and gray segments are intended for conveyors intended for environments with a risk of explosion.